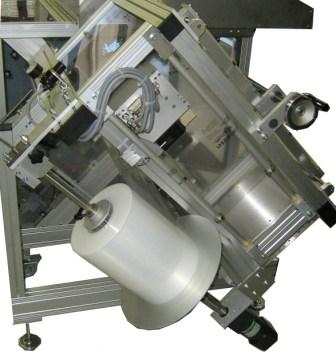

Film Bag Packaging Machines for Flat Films

The packaging machine for poly-tube bags made from flat film

The modular structure is designed so that the DSB 175/300/400 FF can be introduced and integrated as anything from a stand-alone packing machine to a fully automated packaging system. It goes without saying that interfaces for the external management of the machine and marking data as well as a host-connection are already in place.

System Features

- Polyethylene flat film

- Versatile structure-in profile technology

- Filling-pipe quick-change system

- Easy to maintain

Technical details

- Control: Siemens PLC S7-300

- Capacity: up to 35 bags/min

- Bag-width: 60 to 300mm

- Bag-length: infinitely adjustable

- Bag-height: 80 / 140 / 200 mm

- film-strength: 40 bis 150 µm

- Electrical connection: 230 / 400 V, 50 Hz

- Compressed air: 150 l/min, 6 bar

- Measurements: 1250 x 1500 x 1000 mm (LxWxH)

- Weight: approx. 140 kg

Standard

Control

- Siemens PLC S7-300

- Control the number of individual bags, multi-chamber bags and batches

- Day counter and counts the entire quantity

- Data interfaces and preparation of options

- Malfunction message in plain language

- Controlled film unwinding

- Bag-length measurement

- Film-end warning device

Bags

- Bag-chains and multi-chamber bags

- Bag separation/perforation with a knife

- Consistently high weld seam quality thanks to electronic surveillance

Film

- Neutral

- Printed

- anti-corrosive or anti-static film

- Special film on request

Options

Control

- PC control with data management

- Print-mark control for using pre-printed film

- Malfunction message with visual and/or audible signal

Bags

- Poly-tube bag made from flat film

- Eurohole

- bag ear-off perforation along/across

- Oil or water injection

- Product compressor

Conveyance

- Manual workplace with/without dividers

- Manual workplace with built-in table-top scales

- Collection and cartridge belts

- Hopper for stockpiling products

- Oscillating conveyors

- Rotating conveyors

- Weighing and counting devices

Bag marking

- Label dispenser

- Ink stamp

- Ink-jet printer

- Thermal transfer printer

Bag Transport

- Belts of different performances

- Controlled box-filling

- Bag rentention device

- Checkweigher